In the past few years we’ve seen concrete becoming increasingly popular material for countertops. What are the pros and cons of concrete and is it right for you?

Pros

Relatively cheap –

Costs for concrete countertops can range between $65 and $135 per square foot (1.5-inch-thick countertop). Prices can vary depending on materials used, intricacy, time spent designing, and location.

Lots of styling options –

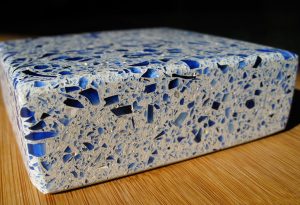

Concrete countertops can be customized in numerous ways. Pigment can be added throughout the entire surface for color, staining the concrete can create the look of marble, granite, or other natural stones.

The edges of concrete countertops can be finished many ways, from a rustic “ragged” looking edge, to an intricate rope detail. Pieces of glass, stone chips, or tile can be added into the surface for a mosaic look.

Seamless

Very large concrete slabs can have seam lines, however by using a color matched filler the appearance of seam lines can be drastically reduced.

Cons

Needs to be sealed-

Concrete is a porous material. In order to protect the look of a concrete counter top it will need to be sealed. There are two types of concrete sealers, those that penetrate inside the concrete, and those that form a protective top layer. Depending on what sealer is used and the amount of countertop usage, you will most likely have to reseal the surface every 1-3 years.

Some people report that even when sealed, certain liquids like coffee, or oil can still leave their mark on the concrete surface. Concrete will also scratch overtime, being most noticeable on dark surfaces. Some owners love concrete for the “patinaed” look that their countertops take on overtime, chalk it up to beauty being in the eye of the beholder, or homeowner in this case.

Heat Resistant (?)

Concrete by itself if fairly heat resistant within reason. That being said, concrete sealant is not a resistent to heat.

Hairline Cracks-

Concrete countertops can be precast off site, or they can be poured on site. Those countertops that have been formed in place are more likely to crack than the precast slab. Houses settle down overtime and things shift, the custom pour countertop is made to fit your house at the time of installation, not 5 years down the road. This leads to hairline cracks in the surface. Larger cracks are easy to fix, smaller cracks may become something you’ll have to live with over time.

There you have it, concrete countertops in a nutshell, check out our other articles on countertop materials.

We’ve gone over the differences in natural stone countertops before, now we’re talking about “Solid Surfacing Material” (SSM). While there may not be as many differences between brands of SSM, we’ll talk about what SSM is and what materials are commonly used in its creation.

We’ve gone over the differences in natural stone countertops before, now we’re talking about “Solid Surfacing Material” (SSM). While there may not be as many differences between brands of SSM, we’ll talk about what SSM is and what materials are commonly used in its creation.