At some point in the last decade, you’ve probably read a think-piece or heard a news story about the downward trend of interest in careers in the trade industry.

Fewer and fewer young people are picturing a future in the skilled trades, and that brings about serious questions about who exactly is going to build America’s homes, plumb the pipes, wire the electronics and HVAC units, and generally fix what gets broken in our country in the decades to come.

While the nation at large might wring their hands at the decreased interest in the trades industry, here at Schrader and Company, we see a crop of passionate, committed young people who strive to hone their craft to the highest of levels. These newest members of our team already demonstrate an elite level of skill, professionalism, and talent. We believe in encouraging the interest of young carpenters, and providing opportunity for them to grow, gain hands-on experience, and make a good living.

We sat down with the newest and youngest members of Schrader and Company to ask them about how they got started in their chosen field, what they’ve learned on the journey so far, and what advice they might have for other young people just starting out.

Their thoughtful answers tell us something we all want to hear: the future of our company, and our entire industry, is safe in their capable, hard-working hands.

Austin S., Project Manager

I first became interested in carpentry and building in high school. I took a lot of fine woodworking classes and a course called “Basic Principles of Construction”, where we built a few small things and then sheds at the end of the year. I ended up really enjoying it.

I chose to pursue this career because of the enjoyment I get out of woodworking and crafting. I also knew that college wasn’t the right path for me.

Working with the Schrader team has taught me everything I needed to know to work my way up to project manager at 21. I’m still not done learning. There is much more to learn as this profession is always changing.

If you know college isn’t for you, never be afraid or ashamed of pursuing a skilled trades career. The knowledge that you take home every day will benefit you in the future guaranteed, and the skills you learn, you can use in every aspect of life.

Sean K., Project Manager

My wife and I had purchased a house and started to do some large renovations to it. We hired out most of the work but I took on some of the smaller projects. Over the next couple of years I took on some larger scale remodeling projects and my passions switched from the work I was doing during my day job to the extracurricular projects I had at home.

I had graduated from college with a degree in economics and worked in the finance field for several years but I grew disenfranchised with the office atmosphere. I felt greater reward from working with my hands and problem solving on the renovation projects in my own home. I was tired of paying people to do the remodeling work I would rather be doing myself. With my wife’s support, I decided to make the jump and make a career change to learn carpentry and construction.

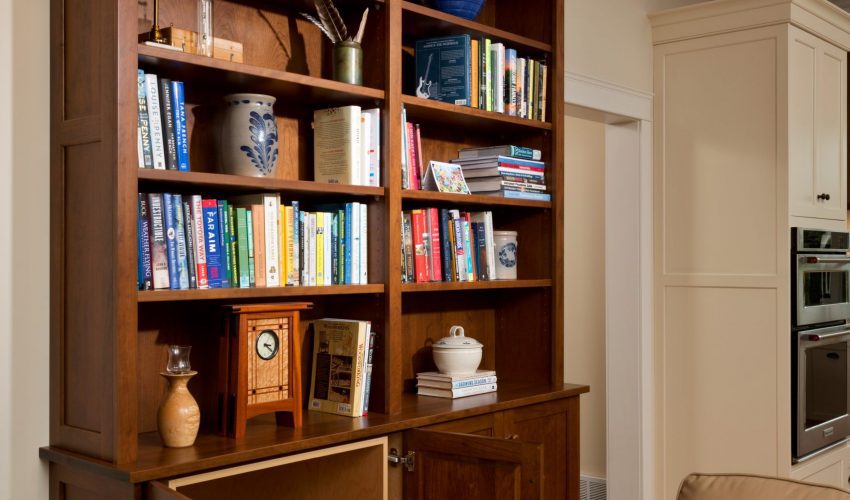

Working with the Schrader and Company team has put me in a great position to learn numerous aspects of the construction field. I have been able to work on a variety of projects that have exposed me to different challenges and experiences. In a world that is going the way of mass produced kits geared to being assembled by anybody, it has been a privilege to be in a position to learn the industry from a company that still exemplifies craftsmanship.

The construction industry can be a very rewarding one. It allows for a full experience of being able to physically involve yourself in the work, but also to engage the mind when needing to find a solution to problems. There is also great enjoyment in being able to be a part of a project from beginning to end, and being able to physically see what you were a part of creating.

Nicco T., Apprentice Carpenter/College Student

Since I was a kid I was always building with LEGO, which led me to take several construction electives at Shenendehowa High School.

During my junior year of high school, my technology teacher saw my interest and pointed me in the direction of the Hudson Valley Construction Tech program. Then during my senior year I was in a class to build a house with my teacher Mr. Verhagan, and I decided to apply for that Hudson Valley course. I am now starting my second semester there soon.

I could fill a page with the skills I have already learned being here at Schrader and Company for almost a year now, but I believe that the team has taught me that putting in hard work will pay off.

If this career path gives you satisfaction after looking at what you have completed after a day of work, then you should pursue this career.

Ryan C., Production Assistant/High School Student

I first learned of my love for carpentry and construction when I was thirteen years old building a workbench with my dad. Once I discovered working with my hands, I inherited some tools from my great grandfather and started to build things on my own, learning something new with every project.

What made me want to pursue construction as a profession was working with and learning from my Uncle Marco, who is a very talented stone mason and an owner of Lazio Construction. He taught me about the different types of construction that I might be interested in and introduced me to Shrader and Company.

Working with the Schrader and Company team has taught me that the area of construction that excites me the most is remodeling and new construction. I have discovered that working on site rebuilding a project or starting a new one, and doing it the right way, has taught me more about my passion for carpentry than I ever could have imagined.

For people who are interested in the trades, I strongly advise them to learn more about the many different paths in construction. Once they’ve found what excites them the most, they should get hands-on experience and they will soon discover that there is never a day or an age where you stop learning something new.